Coming clean about soapy wastewater

Fully featured wastewater treatment system for soap manufacturer

What happens to soapy water after it goes down the drain? The events of the past two years have seen everyone keeping clean by thoroughly washing their hands and constantly rinsing with soapy water. But how do you clean the water that is used for cleaning?

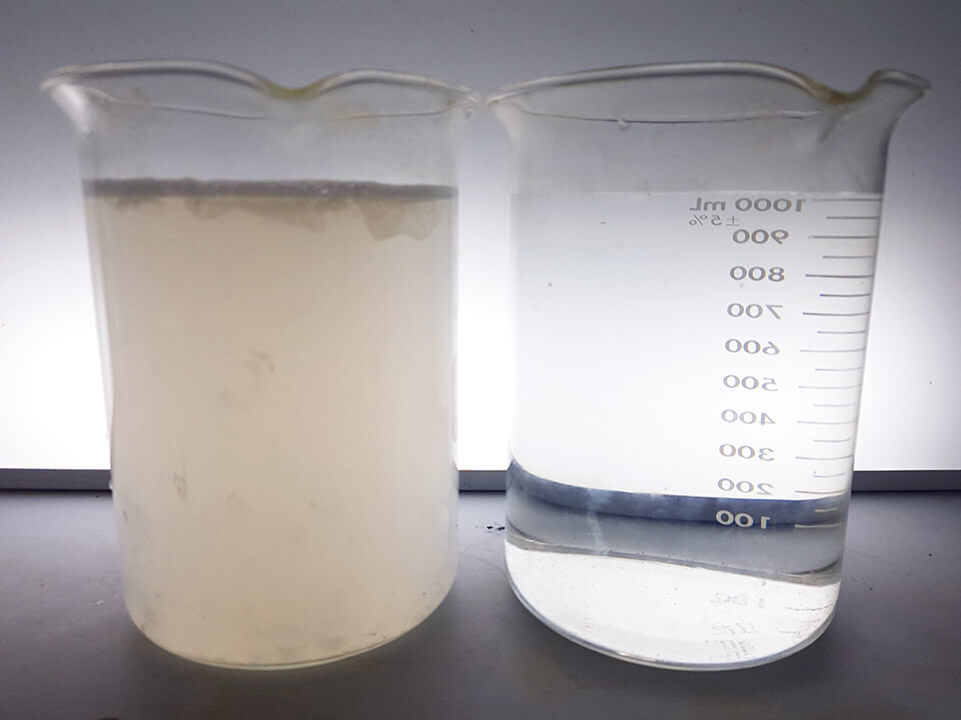

A Toronto-area soap manufacturer approached JNE Environmental to solve this exact problem. As part of the manufacturing process, the client’s production lines are cleaned and rinsed after batches of hand soaps, bodywashes, and shampoos are finished and bottled. The resulting wastewater from this cleaning can be difficult to treat to sewer compliance because of the way the soaps retain contaminants while in the water phase. This contaminant retainment is beneficial for washing and cleaning your hands but can be very challenging for water treatment.

JNE Environmental was up to this challenge. The JNE team designed, proposed, manufactured, and commissioned a full wastewater treatment system for the client. Each component used in this system plays a key role in treating the soapy wastewater to compliance.

The JNE FS-60 DAF unit separating flocculated waste from clear water

FS-60 Dissolved Air Flotation (DAF) Unit

The DAF unit pressurizes air and treated water to generate micro bubbles that attach to the chemically treated and flocculated waste, floating it out of the clear water. The clear water leaves the DAF unit to an effluent equalization system and the sludge waste is pumped to a holding tank.

PM-2000 Polymer Make-Down Unit

JNE has designed the PM series to automatically prepare liquid polymer for the treatment system, minimizing operator involvement. JNE flocculants are shipped as dry, crystalline powder and coupled with a make-down unit so that our customers save on shipping and water costs and avoid expensive solvent emulsion based flocculation products.

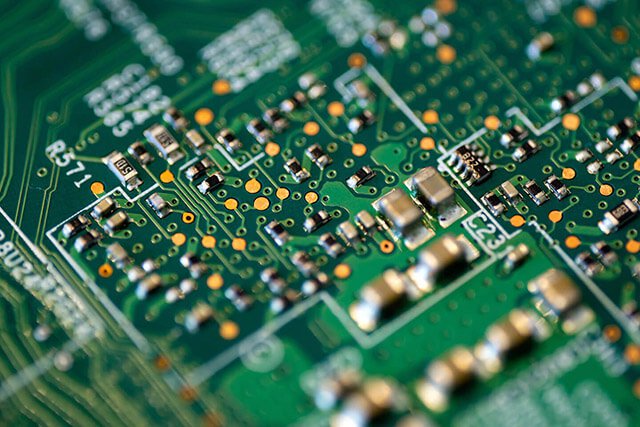

The PLC (programmable logic controller) and touchscreen HMI (human machine interface), designed and programmed by JNE Automation, become the brain and nervous system of the wastewater treatment system. It controls the chemical dosing pumps, water feed pumps, equipment motors, etc., so that operators only need to check on the system rather than operating every component.

JNE Automation commissioning the PLC.

Foam Detection, Measurement, and Suppression Systems

Because this plant manufacturers soap products, the client’s wastewater is prone to excessive foaming. After numerous tests to find the best-suited method of foam detection and suppression, the JNE team designed and installed water spray and anti-foam injection systems to successfully eliminate the foaming as it occurs. Read more about that aspect of the project here.

The finished wastewater treatment installation.

This full wastewater treatment system, installed and commissioned by the JNE Environmental team on-site, is now running smoothly and discharging clear, treated water within sewer by-law compliance.

The untreated vs treated water.

Are you having trouble with soapy water or other types of challenging wastewater? Have you received a notice of violation from the city and need assistance?

With billions of gallons of experience, the JNE Environmental team can help you through every step of the process of achieving sewer by-law compliance. Our expertise and on-site support includes compliance plans, system design, manufacturing, automation, commissioning, and ongoing service and wastewater treatment chemical supply. Contact us today to learn how we can help.

Connect

Services + Products

JNE Environmental is a full-service wastewater treatment company. We supply and manufacture our own wastewater treatment systems, equipment, products and services for a wide range of industrial clients. Our solutions include system design, manufacturing, and supply treatment of FOG, TSS, BOD/COD, metals, pH, and more.