Wastewater Treatment: No Cheesy Affair

Wastewater Treatment: No Cheesy Affair

JNE Environmental was recently approached to investigate performance issues with a Southern Ontario cheese manufacturer’s wastewater pH correction system. Their existing system was not adequately meeting sewer discharge limits and thus a more capable system was required to achieve compliance.

Wastewater from cheese manufacturing can be difficult to treat because it contains significant concentrations of FOG (Fats, Oils, and Grease), TSS (Total Suspended Solids), and Phosphorus, all of which are considered in these sewer by-law limits.

Upon further investigation of the existing wastewater treatment system, our technicians discovered issues that stretched beyond pH compliance and it was determined that additional testing was needed. We installed our rental 24 hour composite sampler to build a wastewater profile and determine an approach that would work best for the client.

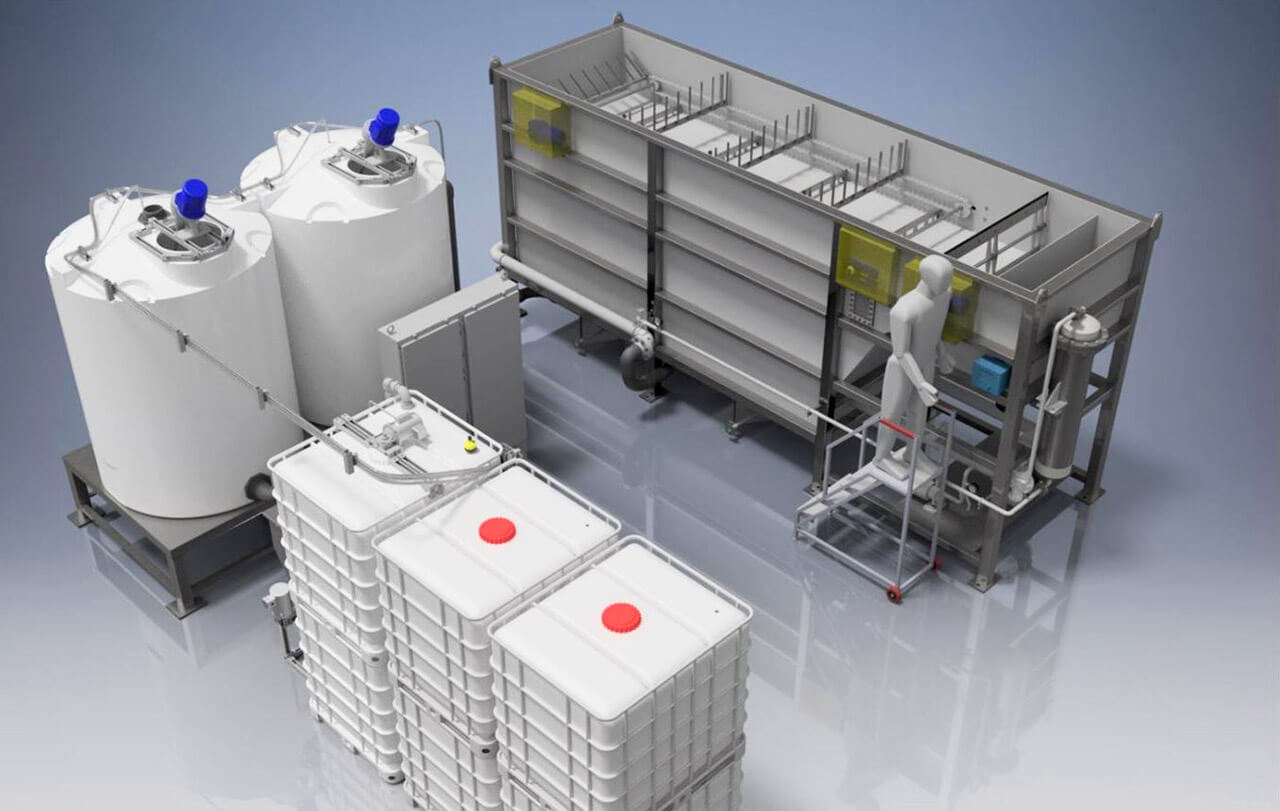

The results of the sampler revealed not only the anticipated pH fluctuations, but also high levels of TSS and FOG. Numerous treatability studies were then performed to determine the optimal chemical and equipment specifications for a full-size treatment system including 3D layout design, operating costs, and estimated chemical consumption.

3D render of the system layout.

JNE was pleased to be awarded a purchase order to help solve this client’s wastewater issue. The scope of work included the design, manufacture, and supply of a custom wastewater treatment system complete with PLC (programmable logic control) automation, as well as a JNE designed and manufactured automatic polymer make-down unit (PM-2000).

Fabrication underway in the JNE Environmental warehouse and shop.

The polymer make-down unit prepares the required liquid flocculant from JNE’s crystalline powder. This liquid flocculant would otherwise be prepared manually, several times a day. The automated PM-2000 system reduces operator involvement and human error in this process. Final fabrication steps are underway and the system components will soon ship to the customer for installation.

Final parts are being installed on the new PM-2000 polymer makedown unit.

Wastewater from cheese manufacturing can be difficult to treat because it contains significant concentrations of FOG (Fats, Oils, and Grease), TSS (Total Suspended Solids), and Phosphorus, all of which are considered in these sewer by-law limits.

Upon further investigation of the existing wastewater treatment system, our technicians discovered issues that stretched beyond pH compliance and it was determined that additional testing was needed. We installed our rental 24 hour composite sampler to build a wastewater profile and determine an approach that would work best for the client.

The results of the sampler revealed not only the anticipated pH fluctuations, but also high levels of TSS and FOG. Numerous treatability studies were then performed to determine the optimal chemical and equipment specifications for a full-size treatment system including 3D layout design, operating costs, and estimated chemical consumption.

JNE was pleased to be awarded a purchase order to help solve this client’s wastewater issue. The scope of work included the design, manufacture, and supply of a custom wastewater treatment system complete with PLC (programmable logic control) automation, as well as a JNE designed and manufactured automatic polymer make-down unit (PM-2000).

The polymer make-down unit prepares the required liquid flocculant from JNE’s crystalline powder. This liquid flocculant would otherwise be prepared manually, several times a day. The automated PM-2000 system reduces operator involvement and human error in this process. Final fabrication steps are underway and the system components will soon ship to the customer for installation.

Are you a food and beverage manufacturer that is having difficulty with an existing wastewater treatment system or been issued a Notice of Violation (NOV) from your municipality?

We may have the answers to your problems. Let us take the worry out of your wastewater. Contact us for a free, no-obligation site visit.

Connect

Services + Products

JNE Environmental is a full-service wastewater treatment company. We supply and manufacture our own wastewater treatment systems, equipment, products and services for a wide range of industrial clients. Our solutions include system design, manufacturing, and supply treatment of FOG, TSS, BOD/COD, metals, pH, and more.