Pilot Plant Automation and Upgrades

Introducing automated operation and new tank components to improve efficiency

Pilot Plant Automation and Upgrades

Introducing automated operation and new tank components to improve efficiency

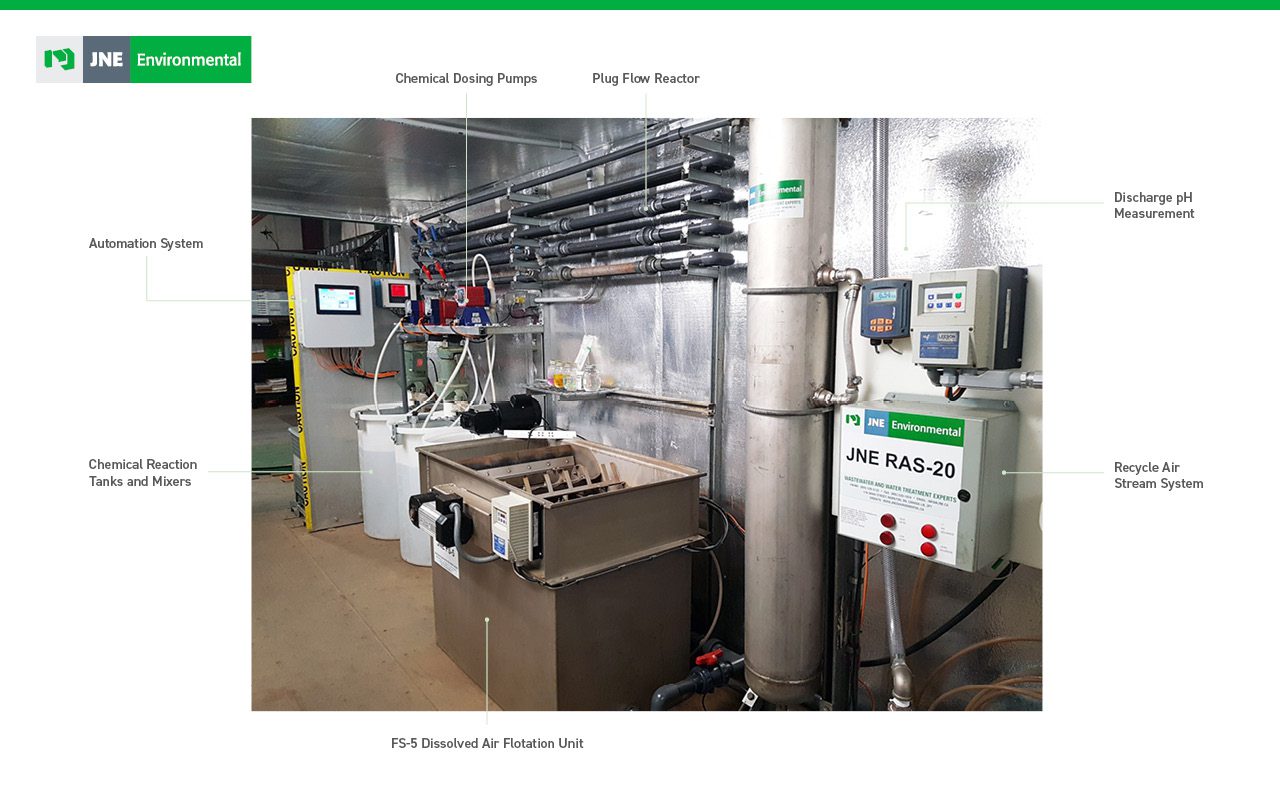

At JNE Environmental, our wastewater pilot plant is a miniaturized DAF (dissolved air flotation) based treatment plant enclosed in a 20 ft sea-can shipping container. Until recently, this small plant would be operated manually by our in-house technicians and used a pipe plug flow reactor for chemical addition and mixing prior to our FS-5 DAF unit.

Continuously looking to improve our products, we identified an opportunity to automate the pilot plant, reducing the required labour to maintain efficient operation.

We added this automation using a cost effective, all-in-one human machine interface (HMI) programmable logic controller (PLC) combination unit. These all-in-one units are a relatively new addition to the automation market, filling a niche where full-scale, high-performance products are not required, but a custom programmed level of automation is still needed.

Our pilot plant was the perfect application for this new technology. The automated system makes our plant easier to operate by automatically running equipment, adjusting chemical dosages based on flow rate and pH, and seamlessly logging all operating and performance data for later analysis. This minimizes the need to have JNE technicians on site to perform these same activities.

The new PLC/HMI for the Pilot Plant.

To improve the versatility of the pilot plant, we also installed mixed reaction tanks below the existing plug flow reactor and made the various chemical reaction systems selectable via a tee branch — one valve sends the wastewater through the pipe reactor and the other valve sends it through the reaction tank system. This makes our pilot plant more versatile as we can easily test different chemical reaction systems for any wastewater.

Some customers may have building or footprint restrictions which require a pipe-based reaction system while others may have enough space for reaction tanks, which result in ease of treatment and more equalization. The addition of this tee branch valve system makes it easy to quickly switch between the two systems, according to what is best for the client.