Automatic foam detection and suppression systems

New methods of measuring foam in wastewater systems

JNE Environmental was contracted by a soap manufacturer in the Toronto area to design and build a foam detection sensor package to enhance foam suppression measures within their plant. This opportunity came about after a successful project completion with the same client in 2020, in which JNE designed and installed a temporary water-spray based foam suppression system.

As noted in this previous case study, foam generated from wastewater and clean-in-place (CIP) procedures can get out of control and overwhelm manhole systems, production room trenches, and treatment tanks. It can be both unsightly and a hazard for workers. This new sensor package, capable of measuring foam height, would trigger the plant’s programmable logic controller (PLC) to automatically deploy water spray and anti-foam suppression measures when a specific height of foam accumulation was detected.

To accurately design this sensor package, JNE Environmental first needed to be able to consistently generate foam similar to what the customer sees in their effluent tanks. To do this, JNE’s technicians created a small-scale mockup with height measurements, a wastewater analogue, and a compressed air bubbler system to produce representable foam.

Testing sensor behaviour with foam.

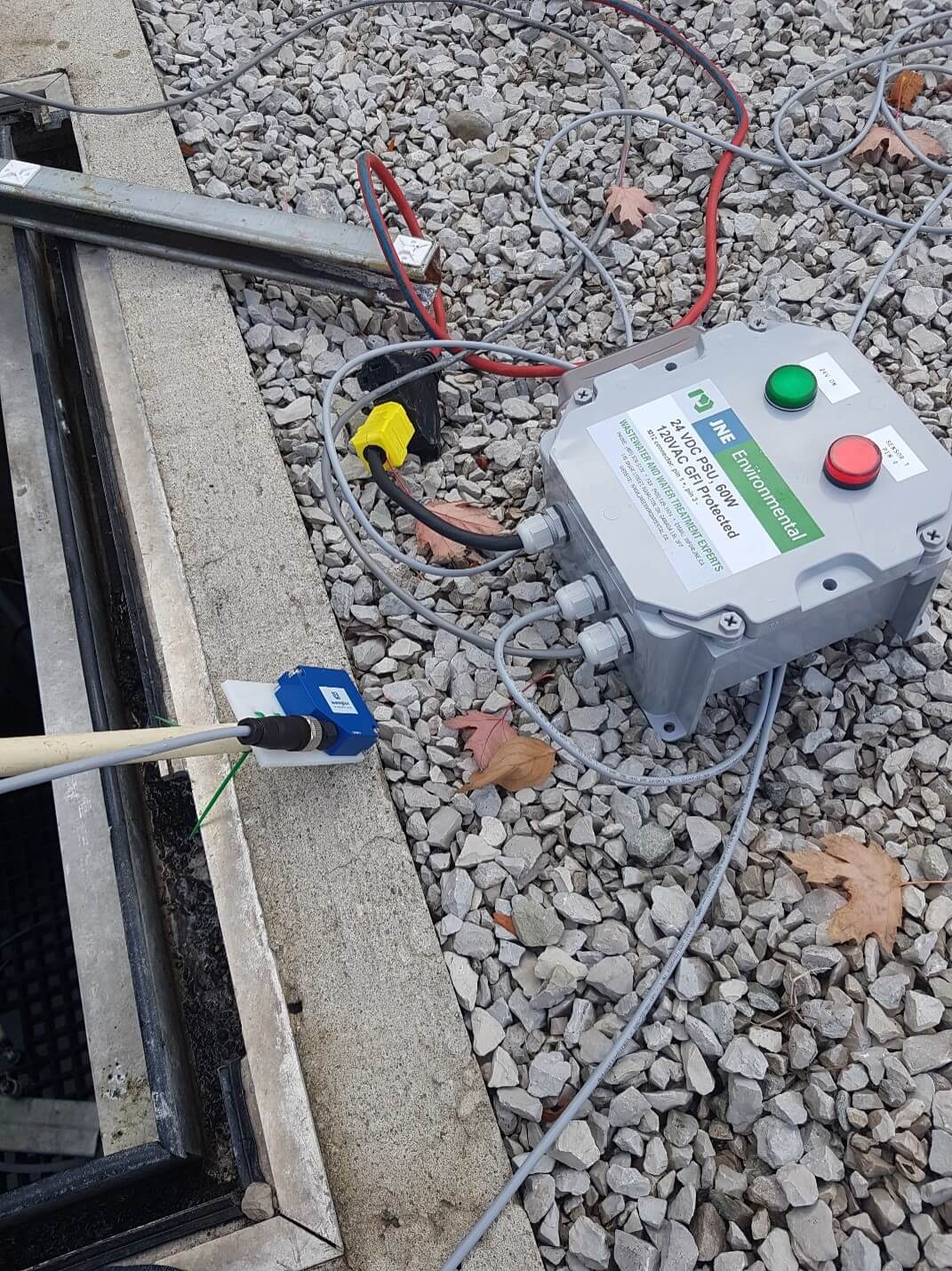

Testing field devices at the customer site.

Once the test setup was ready, JNE evaluated eight different types of sensor technologies. These were tested for digital detection (on/off output), analogue measurement (variable output), variance in trigger height, measurement error, compatibility with countermeasures, and how each handled fouling (foam building up on the sensor).

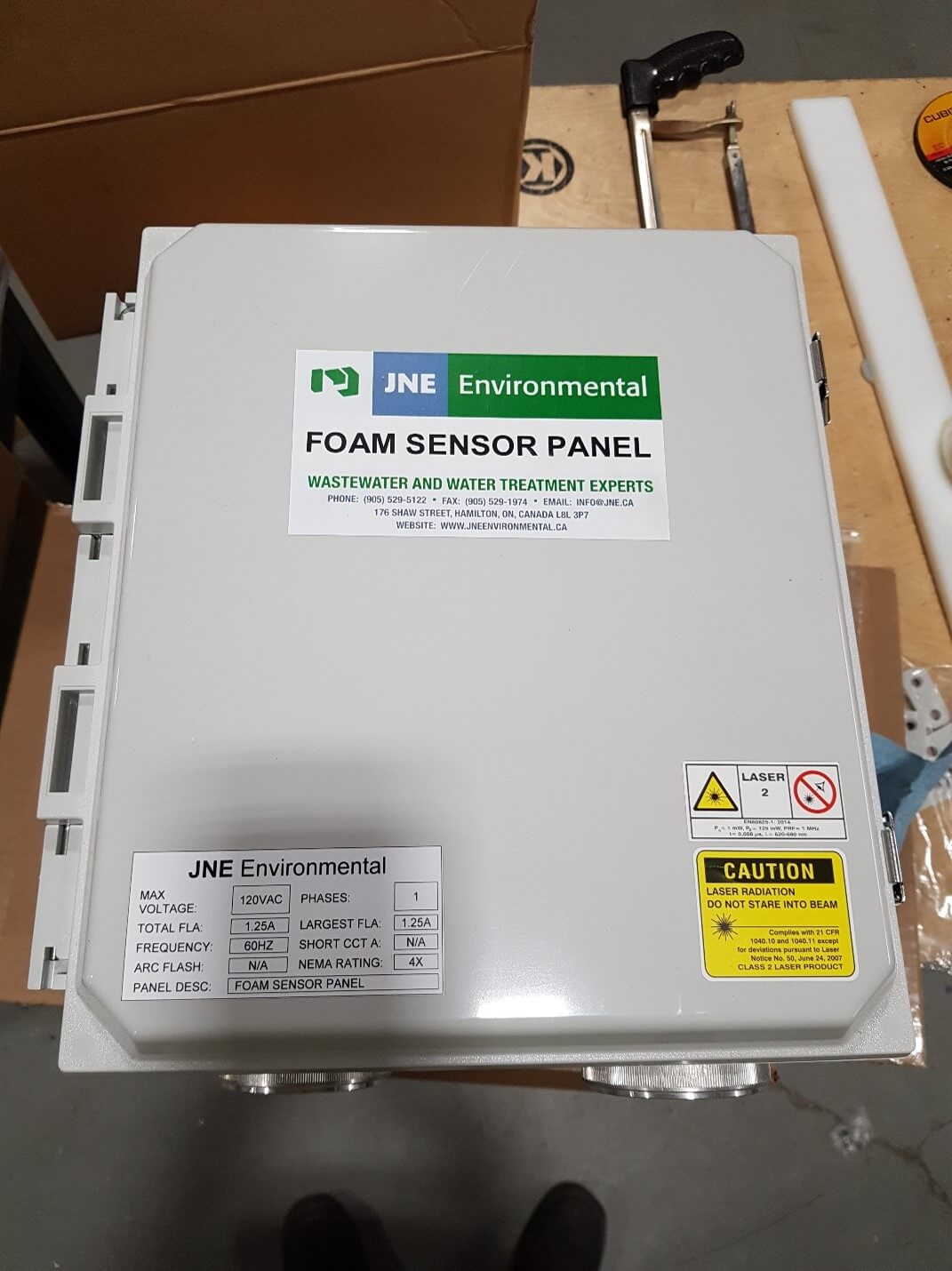

Throughout rigorous testing, two sensor technologies consistently performed better than the others. These sensors then underwent successful testing at the client site and proceeded to be used in the industrial sensor subpanels designed and built in-house at JNE. These water-proof subpanels were then installed in the process effluent tanks as one part of a full wastewater treatment system.

These new sensor packages feature an analogue foam height measurement back to the wastewater treatment PLC, along with a back-up digital high-high sensor. The PLC then triggers foam suppression countermeasures as needed, on demand.

JNE is uniquely able to perform pilot projects for custom technologies for wastewater treatment systems. Do you have a tough wastewater problem with no discernable solution? Contact JNE Environmental to work together towards a solution.