Galvanizing line conversion

Cold rolling and finishing

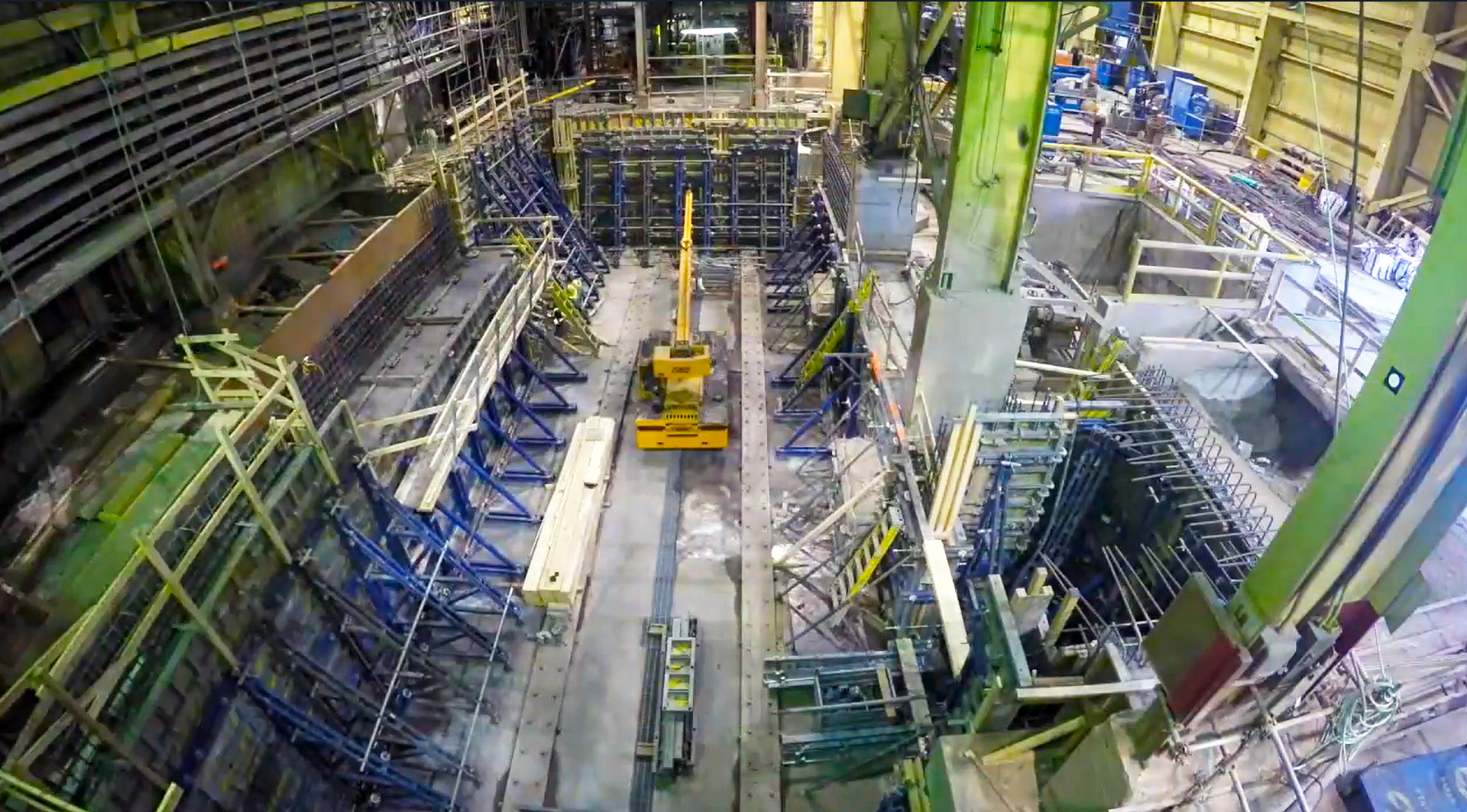

JNE Consulting was asked to submit a proposal to provide detailed construction and infrastructure engineering services for the conversion of Dofasco’s existing No. 4 Galvanizing Line to Galvalume. The project included the same detailed construction and infrastructure engineering services for a new heavy gauge No.6 Galvanizing Line that was to be constructed and designed concurrently. JNE was awarded the construction engineering for both projects.

The conversion to Galvalume required new equipment installation as well as upgrades to the existing line. The major scope items for the project included the installation of a new cleaning process section, a new PreMelt Pot, Launder and Main Pot, new Bath Equipment, a new Water Quench System, a Dual Shuttle Roll Coaster and Dryer System, new Steering Units and Bridle Roll Units, a complete drive upgrade, skin pass mill upgrades, and revamps to both the furnace and Air Pollution Control.

To minimize the shutdown time, a strip by-pass was designed at the entry and exit ends of the line. With the line in a by-pass mode, the project took advantage of installing equipment during line running conditions, greatly reducing production losses due to shutdown time. The new entry cleaning section, as well as a new quench tower support structure and equipment were installed while the line was in normal operating mode.

JNE’s total engineering scope included over 800 drawings spread over five engineering packages. The resulting conversion now allows the No. 4 Line to produce 254,000 tons of Galvalume product per year.

Contact Us