AutoTap Systems

Advanced automation for optimized furnace tapping for Basic Oxygen Furnaces (BOF) and Electric Arc Furnaces (EAF).

The JNE Automation and Nupro solution automates the tapping process, removing the need for manual operator control.

Our partnership provides a complete automated tapping solution, including a vision system to monitor the slag level in the vessel during tapping to control the rate of tapping to minimize slag carryover to the steel ladle.

Our partnership provides a complete solution, including a vision system to monitor the slag level in the vessel during tapping to control the rate of tapping to minimize slag carryover to the steel ladle.

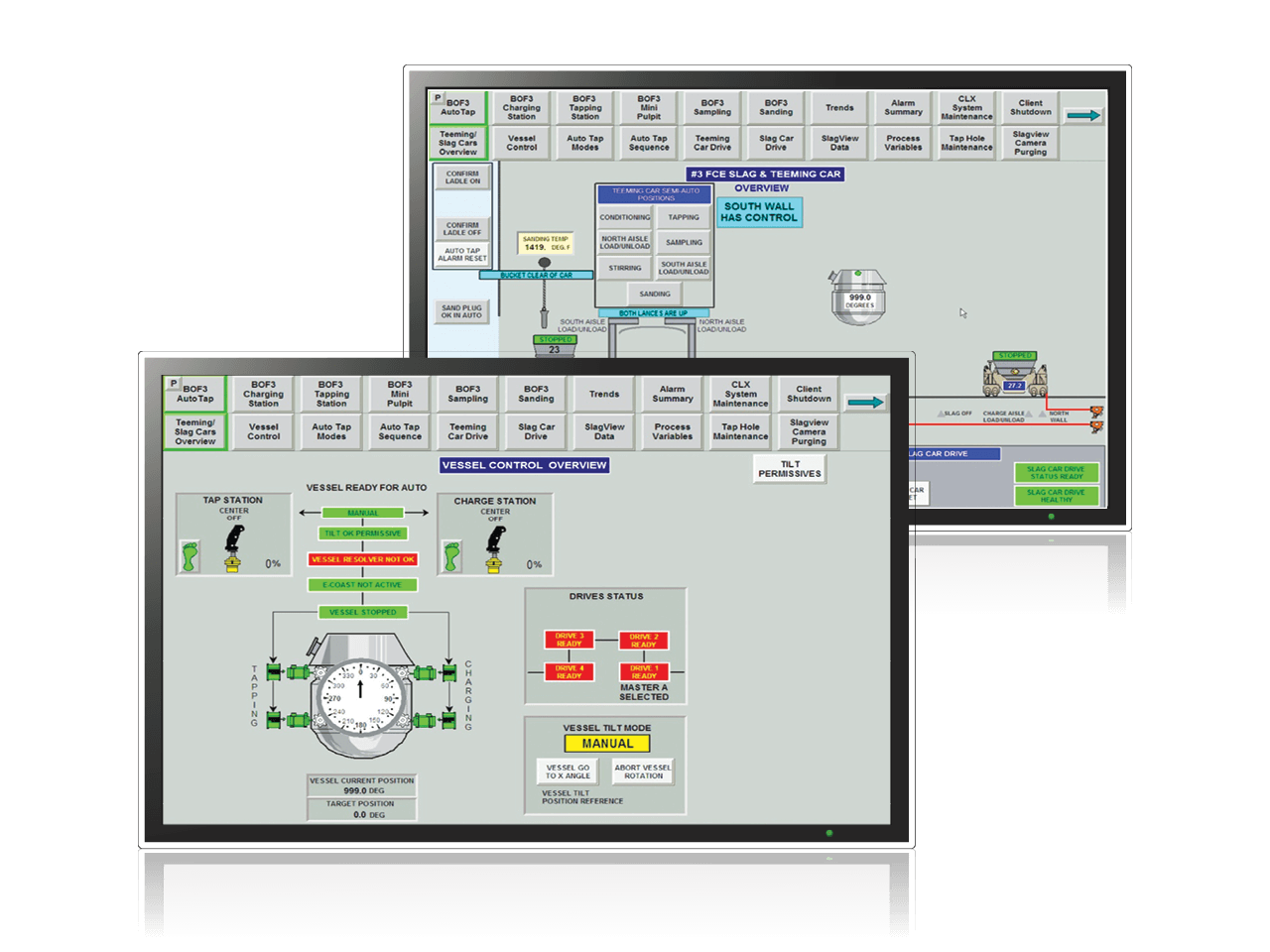

AutoTap Interface

Benefits of AutoTap

Improved

Quality

Controlling the slag carry-over to the steel ladle achieves better Ladle Metallurgical performance and lowers the flux and ladle reheating costs.

Increased

Productivity

Slag raking at the Ladle Metallurgical station is minimized.

Enhanced

Safety

Operator is removed from the vicinity of the molten steel stream during tapping.

Reduced

Costs

Carrying out tapping metallurgy (the addition of alloys and fluxes to the steel ladle during the tap) reduces the Ladle Metallurgical station refining time.

The successful development and implementation of an AutoTap system can achieve improved product quality, increased steelmaking productivity, enhanced operator safety, and reduced downstream processing costs. By following pre-determined customized tapping curves for each BOF, reduced tapping times are achieved and there are less unplanned delays due to inconsistent operation.

Reduced tapping times can allow for more heats per day, increasing throughput and leading to increased productivity. These features result in consistent and repeatable metallurgical specification and production rates.

Connect

JNE Automation’s control systems engineers specialize in continuous process and safety control systems, modernizing PLC and HMI systems, integrating OEM equipment, and supplying custom control panels. Based in Hamilton, Ontario, Canada, we service clients locally, nationally, and internationally.