Cables and

Installation

Methods

Published March 2024

Part 1

Construction of a Power Cable

Conductor

Provides current a conducting path (copper or aluminum).

Insulation

Must be able to withstand the service voltage (impregnated paper, rubber, PVC, cross-linked polyethylene).

Sheath

Protects the insulation from moisture that would affect the insulation & added mechanical protection.

Protective Covering

Share

Part 2

Sizing Electrical Cables

Electrical Code (OESC in Ontario, NEC in USA) determines what size of cable is required.

Electrical cables are sized for current required at the end of the cable.

Conductor diameter mostly increases with current.

Thickness of insulation increases with rated voltage of cable.

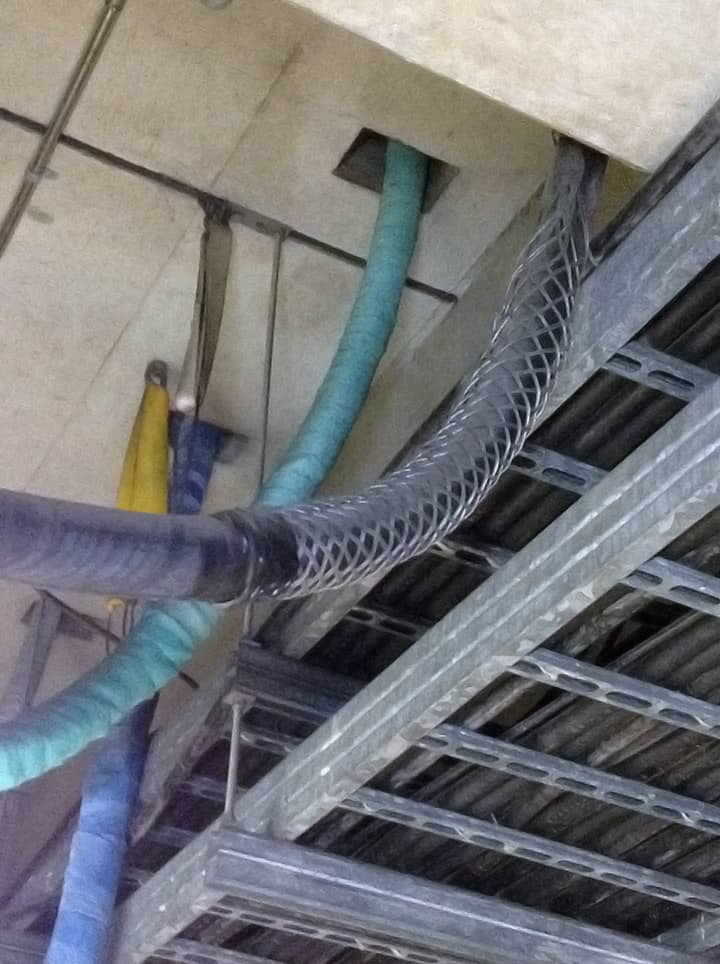

Tray Cable: in cable tray, comes in a variety of insulation and protective shield combinations

MC Cable: Metal-clad, general purpose cable, often used for direct power to small field devices.

Teck Cable: armoured cabled used in industrial environments, can withstand mechanical damage.

Part 3

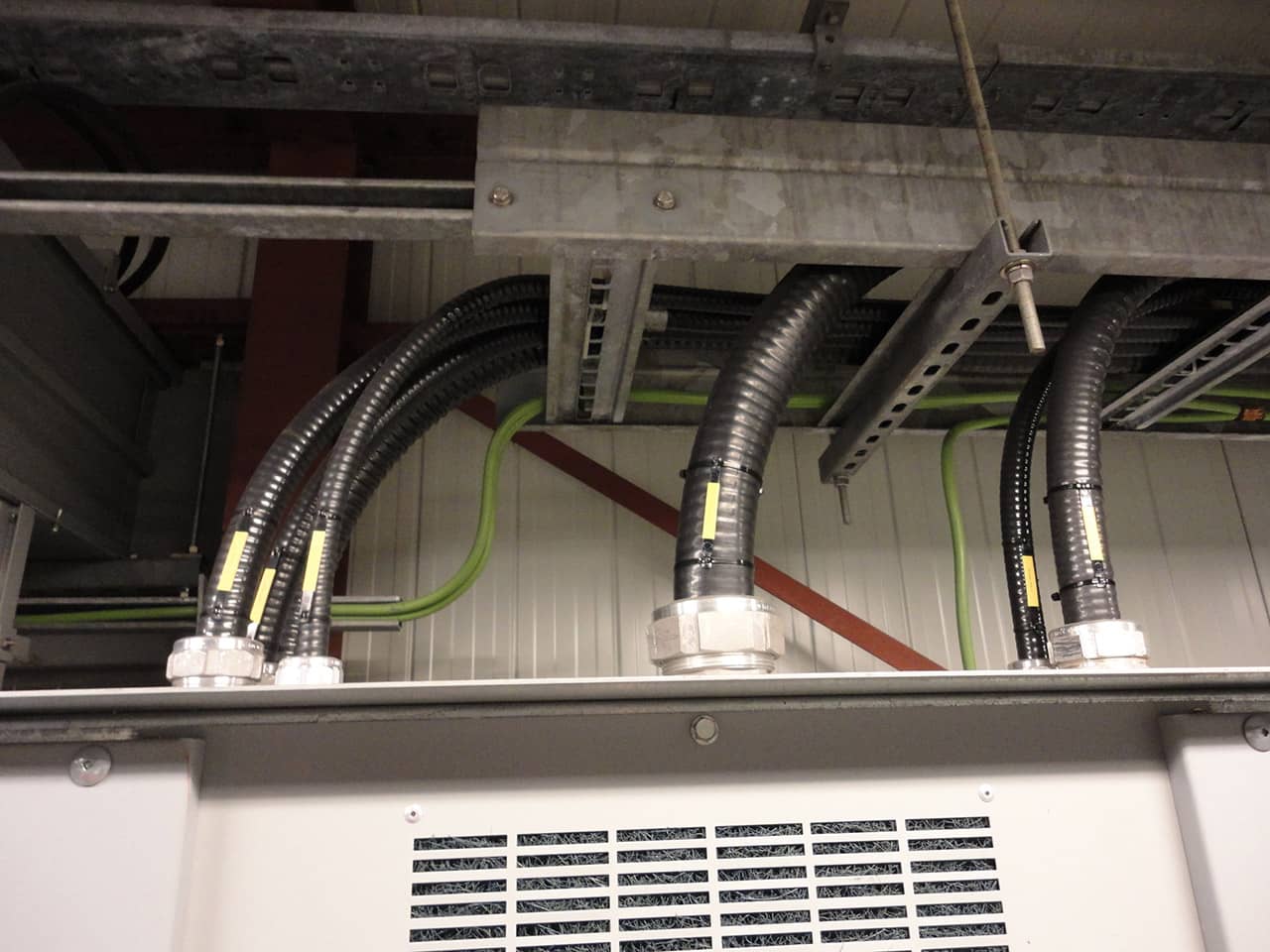

Cable Raceways (Conduits)

An enclosed channel designed to hold cables and wires to protect from heat, humidity, corrosion, physical damage.

RGS: Rigid Metal Steel

IMC: Intermediate Metal Conduit

EMT: Electrical Metallic Tubing

PVC: Non-Metal Polyvinyl Chloride

Flexible Metallic Tubing

The larger the conduit, the larger the bend radius of that conduit.

For larger conduits, bends cannot be created in the field and only a few angles are offered by the manufacturer.

Route of conduit has to be exact to align with knockouts.

Part 4

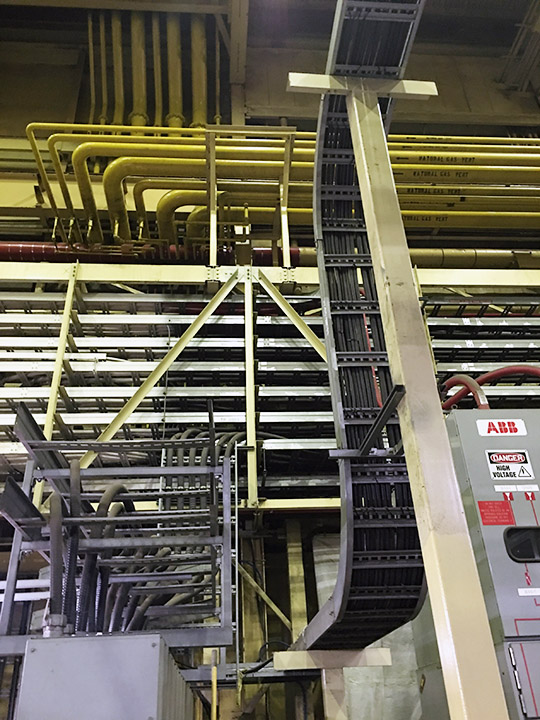

Cable Tray

An assembly of sections forming a rigid structure used to fasten and support cables and other raceways.

Ladder Type Cable Tray

Solid Bottom Cable Tray

Channel Cable Tray

Wire Mesh Cable Tray

The larger the cable, the larger the bend radius of the tray.

Unlike conduit, the end of the cable tray doesn’t have to line up perfectly with equipment knock-outs.

Cables can “waterfall” into a cable tray to ease installation.

Part 5

Conduit or Cable Tray?

Environment

- Harsh industrial environments require complete protection

- Conduits provide a complete seal protecting the cable

- Armoured cable (MC or Teck) can be placed in cable tray and provide a protected option

Cost

- Cable tray is typically cheaper with large quantity of cables

- Further reduction in cost with advanced on-site installation

- 30% cost reduction using armoured cable (MC or Teck) in cable tray compared to EMT conduit*

Cable Raceway and Tray Installation

The collaboration with other disciplines is almost always required for a cable raceway or tray installation.

Civil/Structural input is required to design a cable tray or cable raceway support structure based on the weight per foot.

Good practice is to place cable tray and raceway above utility pipes to avoid the accumulation of moisture and heat.

Underground conduit runs require the input of all disciplines.

Duct banks runs require the input of civil and structural for design and material.

References

- NFPA 70, National Electric Code

- OESC Ontario Electric Code

- CEC Canadian Electrical Code

- Fundamentals of Medium Voltage Switchgear, Eaton, 2020

- Basics of Motor Control Centers (MCCs), EEP, 2020

- VacClad-W, Eaton, 2020

- Mild Steel Splitter Trough, Hammond Mfg, 2020

- Circuit Breaker Fundamentals, Eaton, 2020

- Intelligent motor control center fundamentals, Eaton, 2020

- Variable Frequency drives, Danfoss, 2020

- Definition & Construction of a Cable, Circuit Globe, 2020

- Chapter 11: Raceways, 2020

- Electrical Room Design, Somesh Gaikwad, 2020