Design Features + Benefits

Automation

The PLC monitors the system

to ensure proper operation, including:

- Checking the correct amount of polymer has been added

- Failure to fill the top tank (transfer valve failure)

- Lack of flow when solenoid open (no fresh water feed)

- Presence of flow when solenoid closed (solenoid failure)

- High level in wetting cone (eductor discharge blockage)

- Low dry polymer level in hopper (hopper needs to be filled)

The PLC will change the screen to red when an alarm condition is present and requires operator intervention. It also has a full manual mode for testing and operation of the unit.

Operation

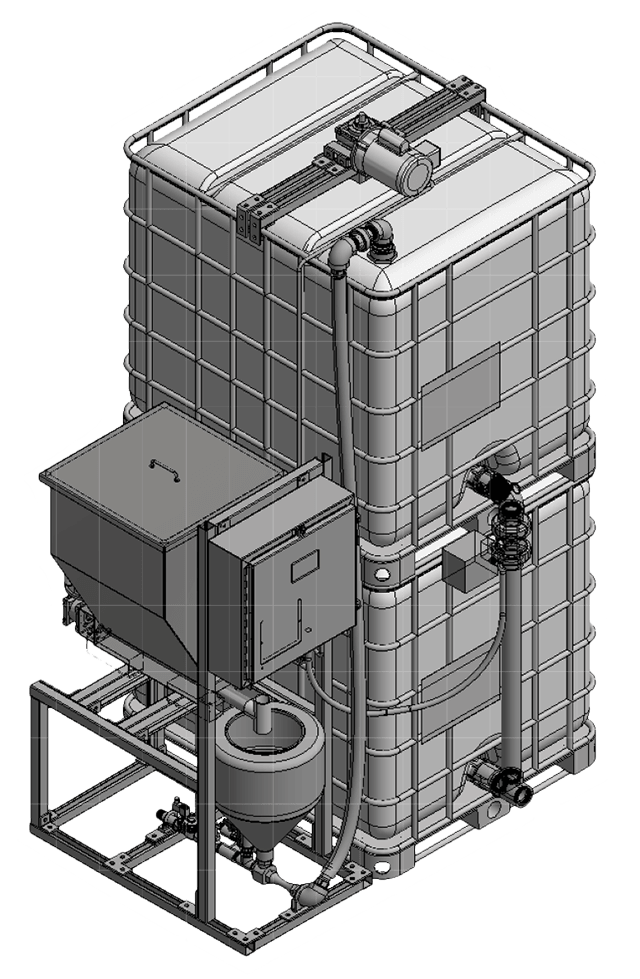

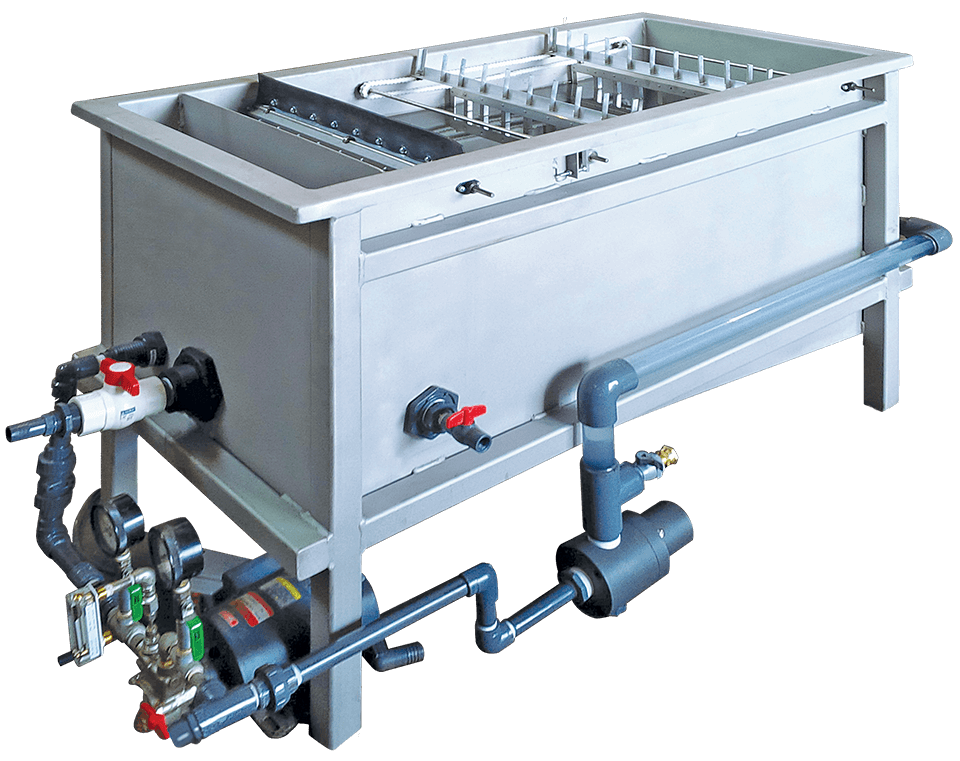

Batch-Based Systems

Incoming city water (min. water feed pressure = 65 psi) is used to fill the aging tank. Once the programmable logic controller (PLC) detects that the level in the aging tank has reached the required set point, the mixer is turned on and the polymer auger is actuated. The PLC measures accurately how much polymer (in grams) has been dispensed into the wetting cone via dual load cells.

Once the desired amount of polymer has been added, the polymer auger is stopped and the top tank is filled.

Incoming city water (min. water feed pressure = 65 psi) is used to fill the aging tank. Once the programmable logic controller (PLC) detects that the level in the aging tank has reached the required set point, the mixer is turned on and the polymer auger is actuated. The PLC measures accurately how much polymer (in grams) has been dispensed into the wetting cone via dual load cells.

Once the desired amount of polymer has been added, the polymer auger is stopped and the top tank is filled.

Aging Process

An operator adjustable timer is used to age the polymer while the agitator is running. When the mixing timer completes, the mixer is turned off and the transfer valve is opened. The polymer solution is then gravity drained or pumped to a run tank for use. Once the PLC detects that the aging tank is empty, the transfer valve is closed and the aging tank is then refilled for the next batch of polymer.

An operator adjustable timer is used to age the polymer while the agitator is running. When the mixing timer completes, the mixer is turned off and the transfer valve is opened. The polymer solution is then gravity drained or pumped to a run tank for use. Once the PLC detects that the aging tank is empty, the transfer valve is closed and the aging tank is then refilled for the next batch of polymer.

Utility Specs

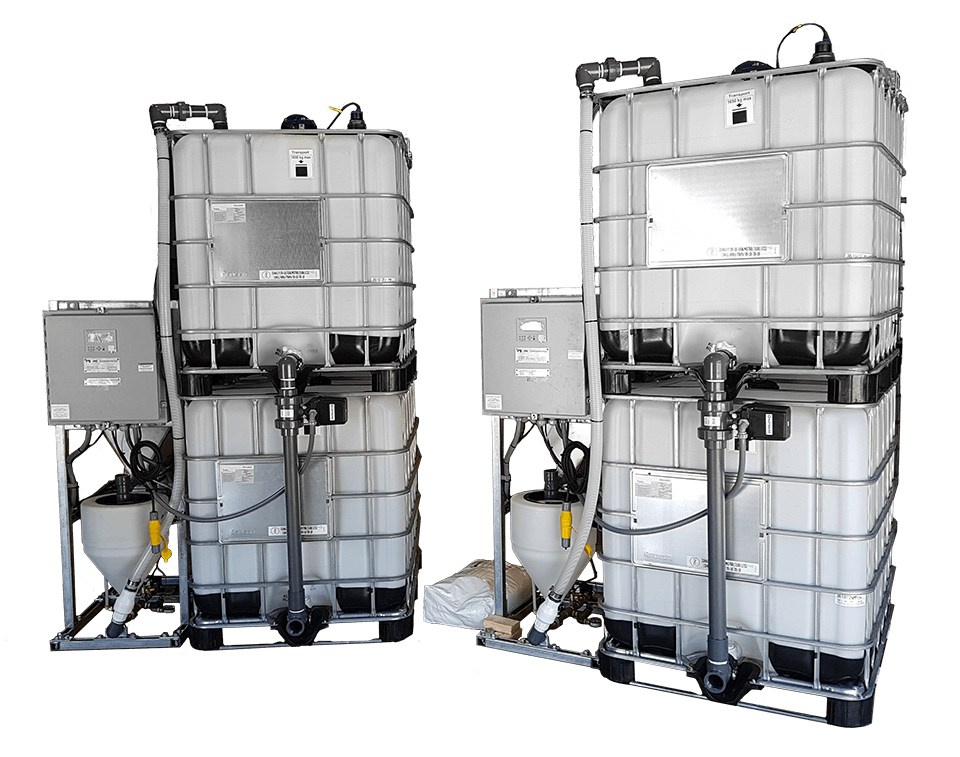

Economical + Versatile PM-2000

Custom Configurations

Made in Ontario

Unlike many of our competitors, we manufacture our own equipment locally in Ontario instead of rebranding machinery from overseas. All of our products use locally sourced steel and equipment promoting North American businesses.

Unlike many of our competitors, we manufacture our own equipment locally in Ontario instead of rebranding machinery from overseas. All of our products use locally sourced steel and equipment promoting North American businesses.

Connect

Services + Products

JNE Environmental is a full-service wastewater treatment company. We supply and manufacture our own wastewater treatment systems, equipment, products and services for a wide range of industrial clients. Our solutions include system design, manufacturing, and supply treatment of FOG, TSS, BOD/COD, metals, pH, and more.