News

Safety Considerations for Pneumatic Pressure Testing

Message Message Safety Considerations for Pneumatic Pressure Testing Safety Considerations for Pneumatic Pressure Testing Published October 2023 Download (coming soon) Keywords Pneumatic Pressure Test Stored Energy Minimum Safe Distance Scaled Consequence Factor ASME PCC-2 Repair of Pressure Equipment and Piping Share Summary Pneumatic pressure testing poses a significant health and safety risk due to the stored energy of the test gas, especially on larger volume piping. This can affect the operations of clients or construction activities and should be considered when specifying pneumatic pressure tests. Safe distances for personnel are proscribed in ASME PCC-2 Repair of Pressure Equipment and Piping. Minimum safe distance is 30m (100ft) and increases with stored energy and risk of fragments being thrown. The safe distance can be reduced utilizing mitigation techniques included in ASME PCC-2. When specifying a pneumatic pressure test always consider stored energy and look to eliminate the need for the testing or substitute hydrostatic. Reducing the safe distance below 30m (100ft) should [...]

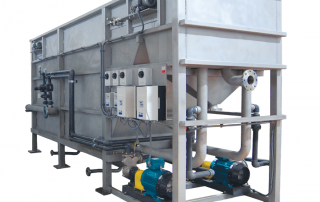

Solving Excess Wastewater Problem for Greenhouses

Greenhouse growers may run out of holding capacity for rainwater during the Spring and Fall rainy seasons. Because this rainwater and plant run-off contacts rooftops, floors, plants, etc., it often has pollutant levels surpassing provincial limits for discharge to the natural environment. By reversing a standard wastewater treatment process, JNE’s pilot plant can safely discharge excess water run-off while recycling and storing nutrient-rich water for production use.

Wastewater Treatment: Drilling, Tunneling, and Mud Separation Polymers

Modern day mining, tunneling, jet and pressure grouting, drilling, and similar activities require a lot of water for operation. These industries use water to remove ground material, cool and lubricate machinery, and control dust. This contaminated water cannot go back into the ground as it may bring these pollutants directly into other important underground water sources such as aquifers and water tables. Luckily, JNE Environmental has the solution.

Wastewater success for skin care and beauty products manufacturer

Wastewater from skin care and beauty products manufacturing can be very difficult to treat due to the complex ingredients used. When JNE Environmental was approached to perform testing on wastewater from a cosmetics manufacturer, we were excited to see how we could treat all levels to within sewer by-law compliance limits.

Contact

us.

Contact

us

Need assistance with your next engineering project? We’re here to help.

We use proven technologies, systems, and work processes to deliver your projects safely, on time, and within budget.