Batch Anneal and Temper Mill Facility Conversion

Wrap-Around Engineering for Operating Facility Conversion

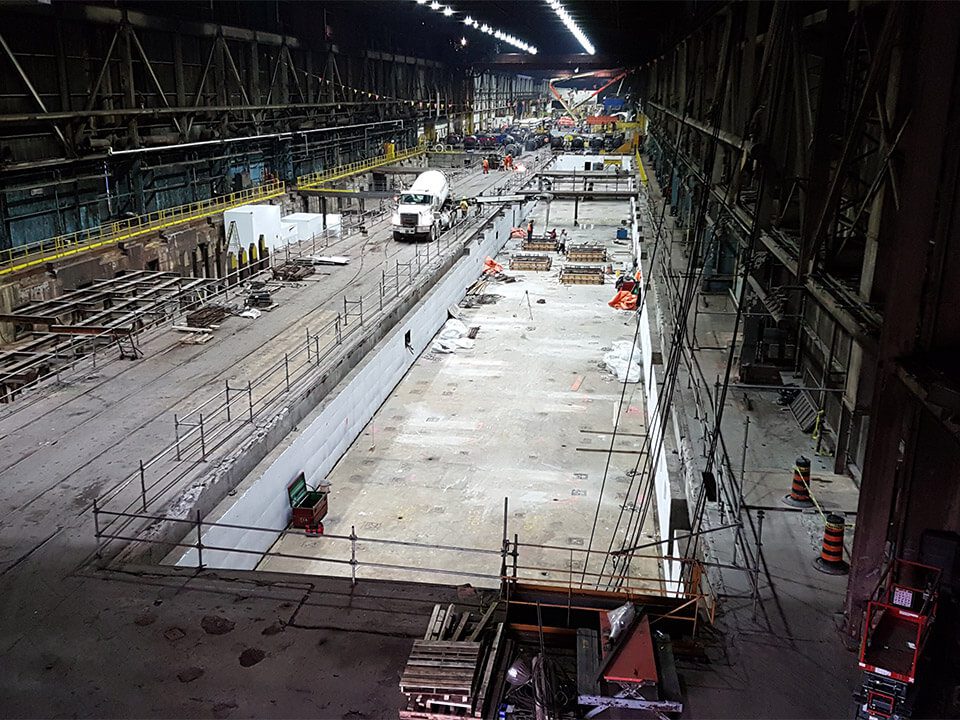

A major steel producer in Hamilton, Ontario was converting their existing batch anneal and temper mill facility to a new hydrogen batch anneal operating facility. JNE was contracted to aid in the demolition of the existing equipment and the subsequent installation of the new equipment, and design of new utilities supply, electrical supply and support structure.

The new batch anneal facility is sized for a minimum production of 200,000 t/year and includes 12 workbases, 6 heating bells and 6 cooling bells. A new Automated Guided Vehicle (AGV) transports coils from the batch anneal facility to the temper mill building. A temper mill was also refurbished, to process the new coils. Lastly, a paper wrapper was installed in the building to wrap the finished coils.

JNE provided the wrap-around engineering, including the power and utilities to the new equipment, support structure design and platform design. JNE was also responsible for coordination with vendors and contractors, engineering project management, construction project management, and health and safety inspections.

JNE implemented several cost-savings solutions to the project, including:

Batch Anneal

- Calculations that proved the existing stack could be reused;

- Clean, efficient, and organized layout of equipment that maximized the space available, including routing of pipes and cables down common paths.

Temper Mill

- Adapting the 4-Stand roll change car to the conditions at the temper mill, including the re-use of existing floor plates.

The project scope continued to increase throughout the life of the project. JNE demonstrated an ongoing dedication to work with multiple stake holders, vendors, and contractors to see the large-scale project completed successfully.

Contact Us