Emulsified Oils vs. Grease Traps

What you need to know about taking your FOG from Notice of Violation to Compliance.

Are you a food, beverage, soap, or cosmetics manufacturer? Perhaps you operate an industrial laundry facility? Have you received a Notice of Violation (NOV) for Fats, Oils, and Grease (FOG) in your wastewater? You might be considering installing a grease trap or oil interceptor at your facility to fix this. However, there is more to this process than meets the eye. Before taking action, we encourage you to learn from our experience with emulsified oils in grease traps, which can help you make a more informed decision with your wastewater treatment and save money for your business.

We often have new customers come to us after installing large, underground grease traps and interceptors with little to no reduction in FOG.

If this sounds familiar, your FOG contaminants are likely emulsified. Typically, interceptors float free oil to the top, particulate sinks to the bottom, and wastewater goes out the middle layer to the sewer. However, if the FOG is emulsified, it won’t float to the top layer and will stay in the water.

Just like hand soap takes the dirt and grease off your hands and goes down the drain, industrial cleaners, by-products, and chemical additives also trap oils and grease in the water phase, emulsifying them. Once emulsified, they cannot float to the surface as the interceptor design intends.

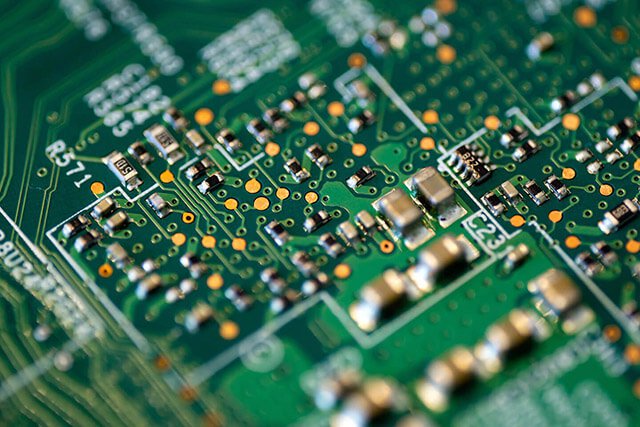

Underground inceptor tanks at a local soap manufacturer that are now used as influent and effluent equalization tanks as part of our DAF-based treatment process.

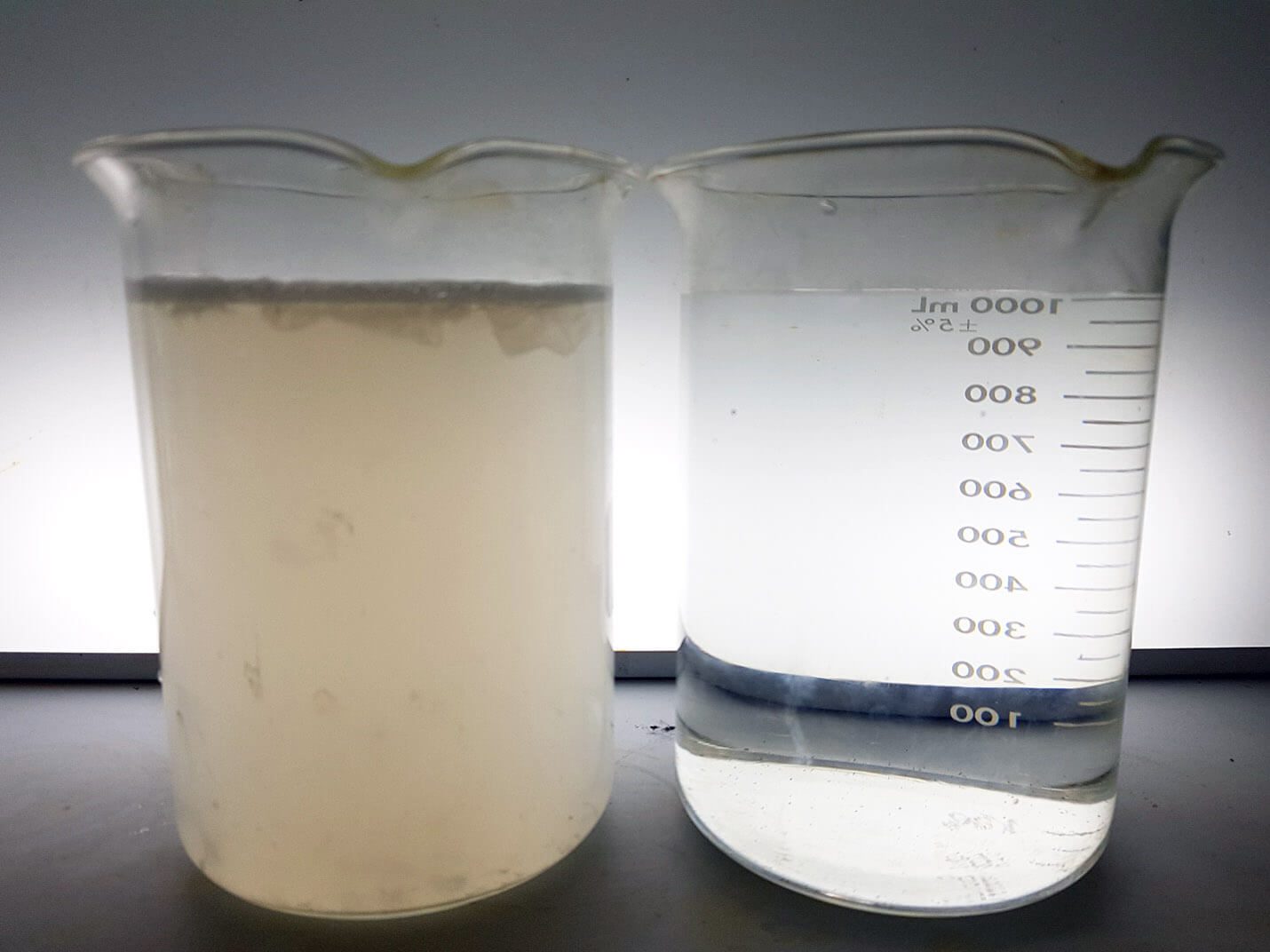

Wastewater with emulsified FOG from the interceptor tanks, before and after our DAF-based treatment system.

This is where physiochemical separation comes in. We use coagulation, flocculation, and finally a Dissolved Air Flotation (DAF) unit to separate the contaminants from the clear water, typically removing over 95% of FOG. The sludge waste is disposed of and the FOG-free water goes down the sewer.

If you’ve already installed a grease trap or interceptor that isn’t working, don’t’ fret — your investment isn’t wasted! Interceptors are still used as small equalization tanks or transfer sumps as part of a more complete chemical-based treatment system.

Emulsified FOG-laden wastewater from an interceptor (left) and after our treatment process (right) at a local cheese manufacturer.

A JNE FS-60 DAF unit separating the FOG waste and clear water, from the previous picture.

For a demonstration on how you can test for free FOG, calculations, and data results from a customer case, refer to part 1 of our municipal presentation, available here.

If you’re thinking about installing a grease trap or interceptor, or already have one that doesn’t work, reach out to us; we can help you achieve sewer by-law compliance with our cost-effective treatment chemicals and Canadian-manufactured DAF equipment.

Contact Us

Contact Us

With billions of gallons of experience, there is almost no wastewater issue we can’t solve. Reach out today for a free, no obligation site visit to your facility.

925 Century Drive

Burlington, ON L7L 5J8

Tel: 905-529-5122

enviroinfo@jnegroup.com

Companies

Connect

Services + Products

JNE Environmental is a full-service wastewater treatment company. We supply and manufacture our own wastewater treatment systems, equipment, products and services for a wide range of industrial clients. Our solutions include system design, manufacturing, and supply treatment of FOG, TSS, BOD/COD, metals, pH, and more.