Electrical Clearances: Best Practices

Working space around electrical equipment.

Electrical Clearances: Best Practices

Published February 2026

Keywords

Share

Background

When sizing a room, or an area that will house electrical equipment, there are many variables to consider.

It is clearly stated in the Ontario Electrical Safety Code (OESC) book that “electrical equipment shall be installed and guarded so that adequate provision is made for the safety of persons and property and for the protection of the electrical equipment from mechanical or other damage to which it is likely to be exposed” (OESC 2-200). This can be done with a dedicated electrical room/space, signage, physical barriers, and training. When working with other disciplines, the electrical team must communicate the physical size, and space needed to follow all of the rules stated in the OESC, of the chosen electrical equipment.

Example

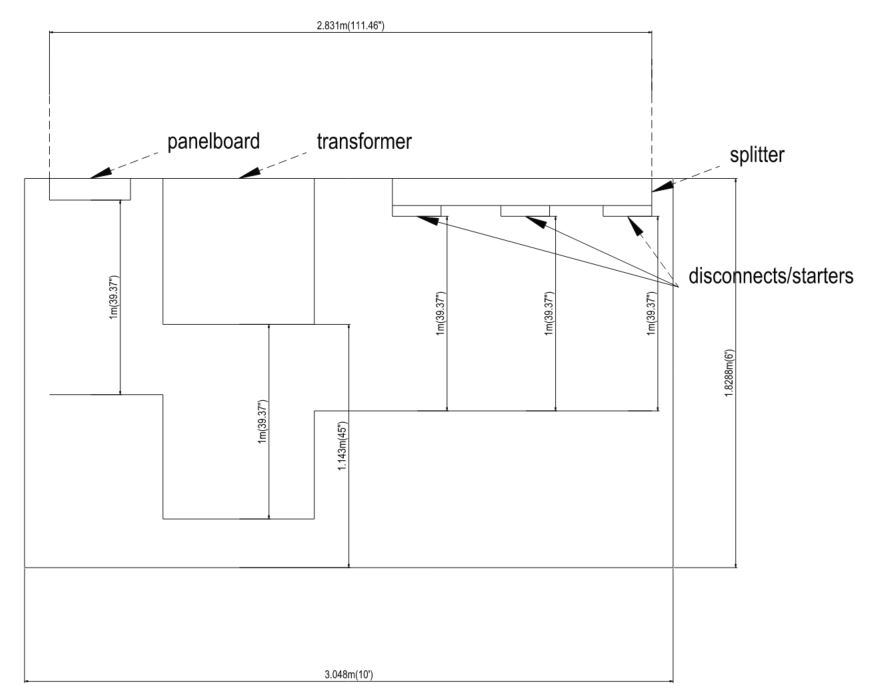

In a recent project, a new electrical room was needed for all the new electrical equipment. Using the physical size of the electrical equipment, the minimum size of the room was determined to be 10’ by 6’ (see Figure 1).

Figure 1

The following rules were used to come to this conclusion:

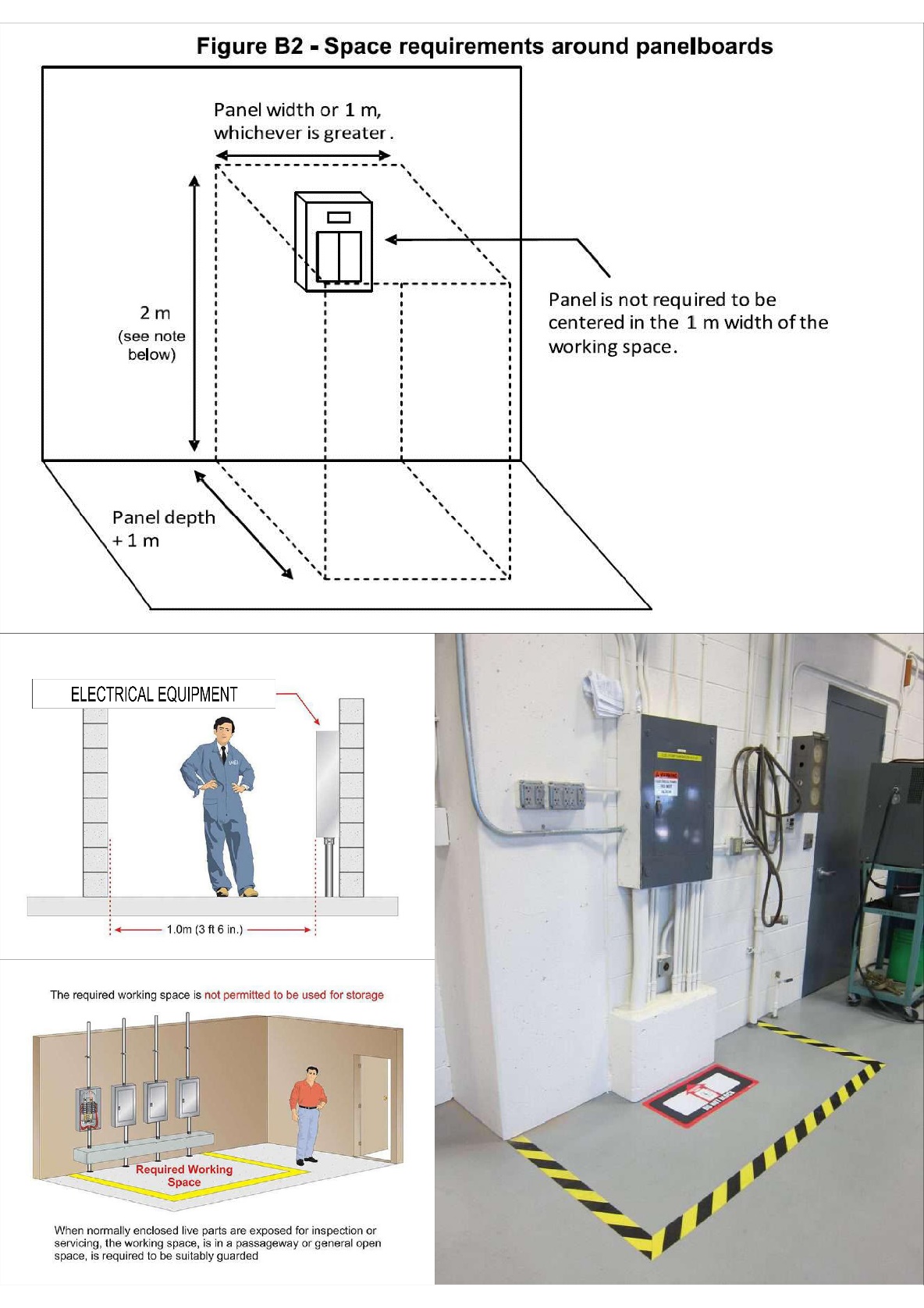

- OESC 2-308: Working space around electrical equipment.

- A minimum working space of 1 m with secure footing shall be provided and maintained about electrical equipment that:

- a) contains renewable parts, disconnecting means, or operating means, or;

- b) requires examination, adjustment, operation, or maintenance.

- The working space referred to in Subrule 1) shall not be required behind equipment where there are no renewable parts such as fuses or switches on the back and where all connections are accessible from locations other than the back.

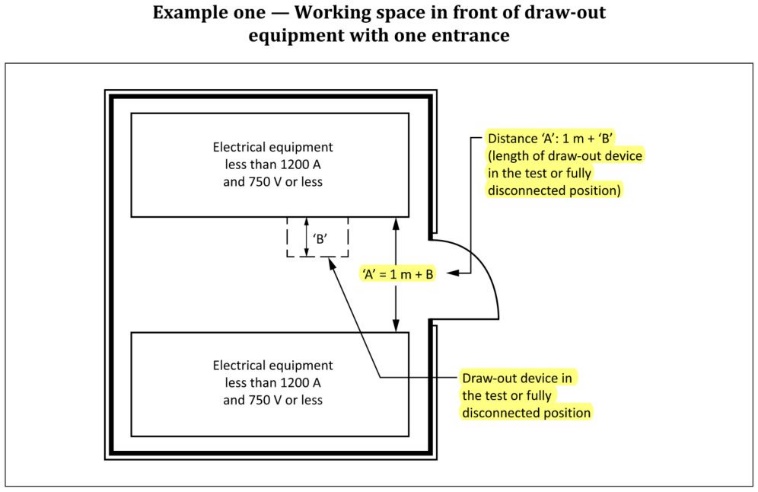

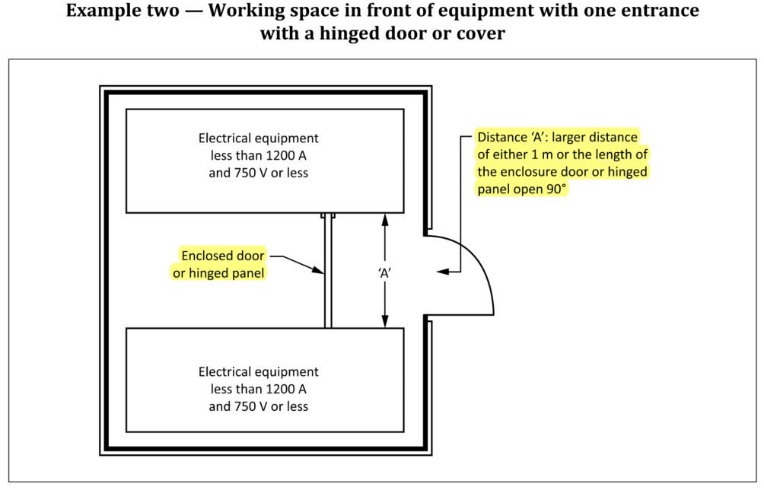

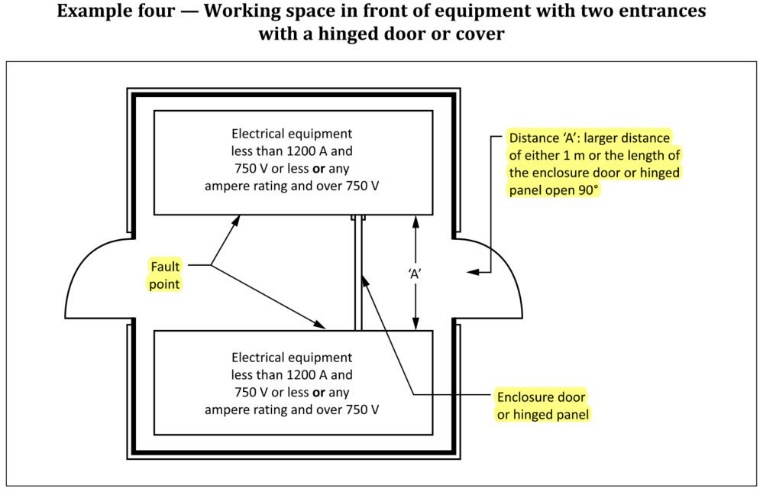

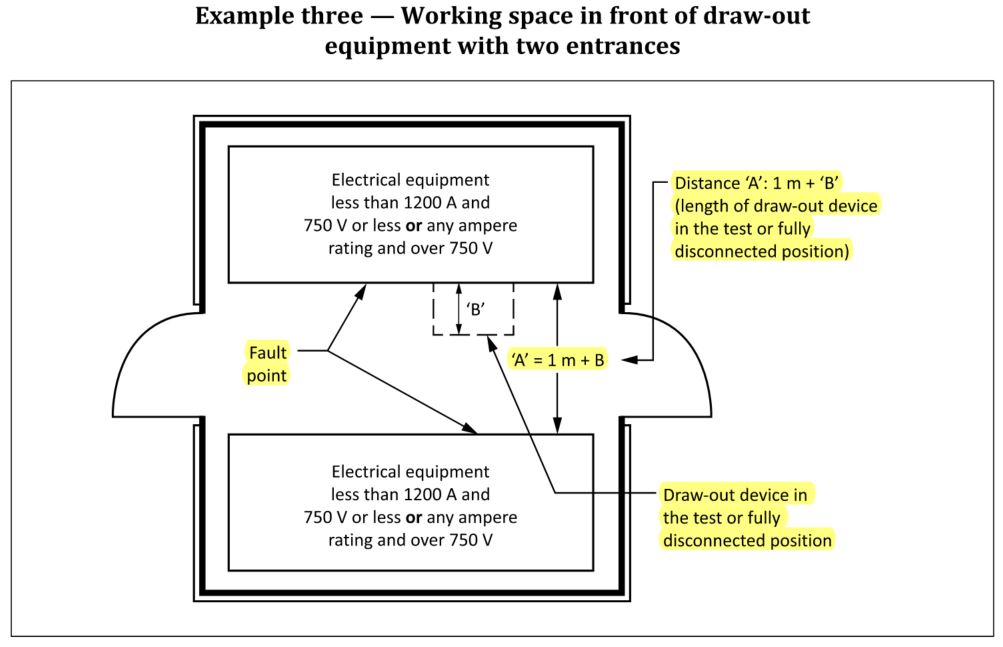

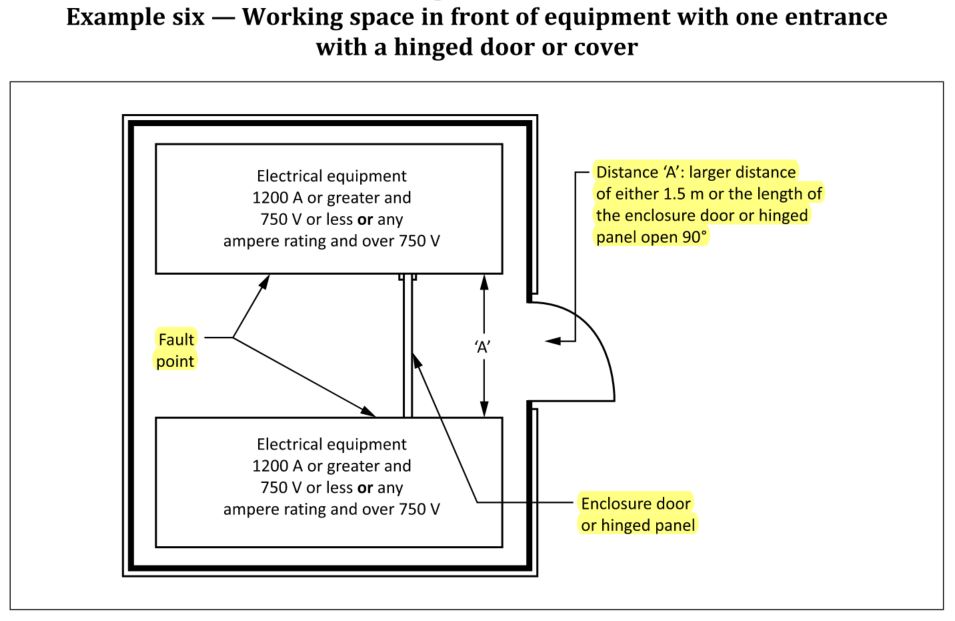

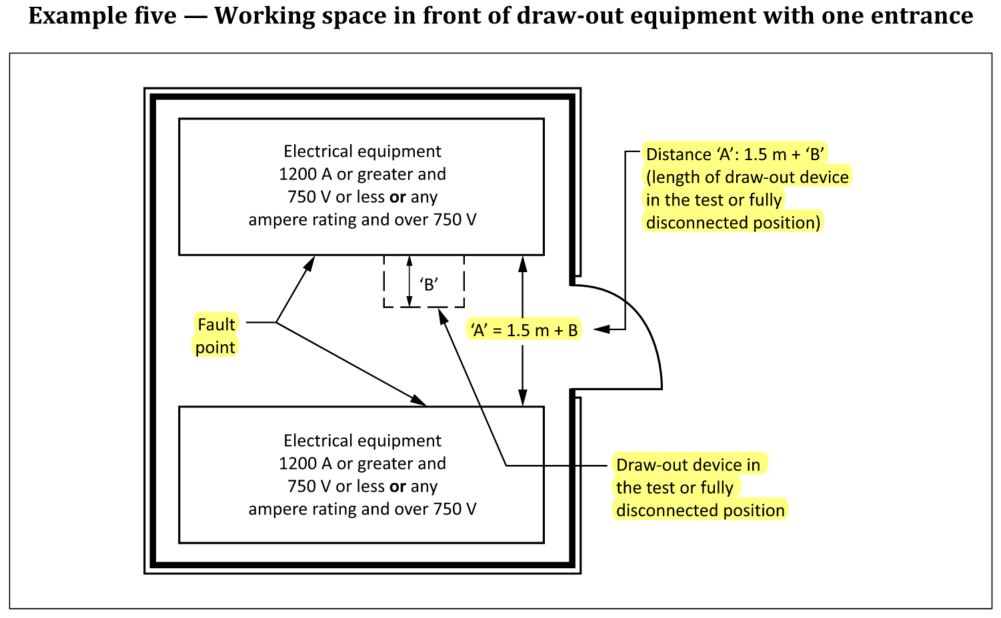

- The working space referred to in Subrule 1) shall be in addition to the space required for the operation of drawout-type equipment in either the connected, test, or fully disconnected position and shall be sufficient for the opening of enclosure doors and hinged panels to at least 90°.

- Working space with secure footing not less than that specified in Table 56 shall be provided and maintained around electrical equipment such as switchboards, control panels, and motor control centres having exposed live parts.

- The minimum headroom of working spaces around switchboards or motor control centres where bare live parts are exposed at any time shall be 2.2 m.

- A minimum working space of 1 m with secure footing shall be provided and maintained about electrical equipment that:

- OESC 2-310: Entrance to, and exit from, working space.

- Each room containing electrical equipment and each working space around equipment shall have unobstructed means of egress in compliance with the National Building Code of Canada.

- Where a room or space referred to in Subrule 1) contains equipment that has a rating on the equipment nameplate of 1200 A or more, or is rated over 750 V, such equipment shall be arranged so that, in the event of a failure in the equipment, it shall be possible to leave the room or space referred to in Subrule 1) without passing the failure point, except that where this cannot be done, the working space requirement of Rule 2-308 1) and 2) shall be not less than 1.5 m.

- For the purposes of Subrule 2), the potential failure point shall be any point within or on the equipment.

- Doors or gates shall be capable of being readily opened from the equipment side without the use of a key or tool (see Appendix B).

Appendix B

- Door hardware that is not considered to meet the intent of this Subrule includes a door or gate that:

- Requires a key to exit the room;

- Is equipped with a door handle and one or more additional devices such as a deadbolt; or

- Requires other special devices or specialized knowledge to exit the room.

When sizing an electrical room, proper illumination to perform any maintenance must also be considered:

2-320 Illumination of equipment:

- Adequate illumination shall be provided to allow for proper operation and maintenance of electrical equipment.

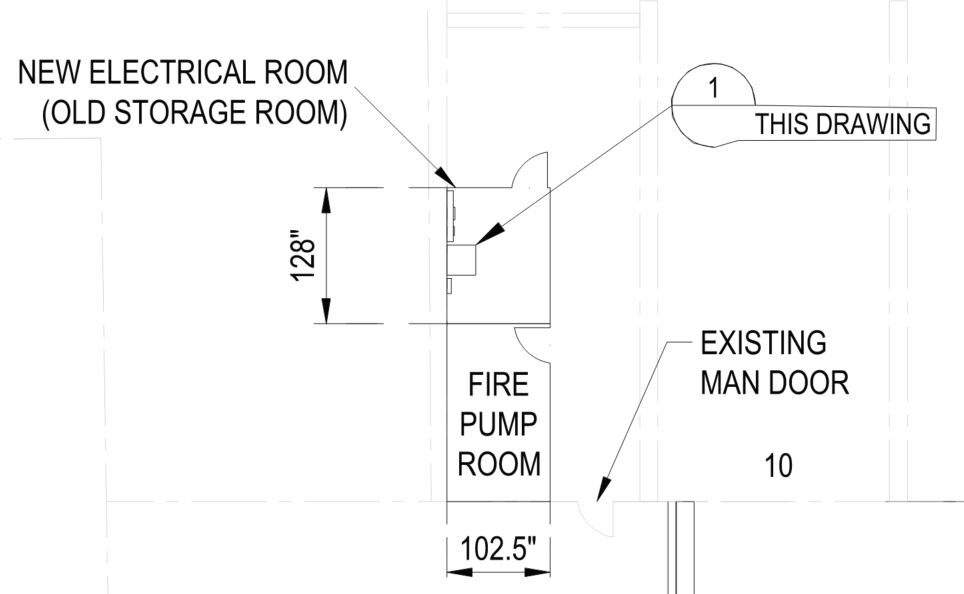

While these rules are required for a new electrical room, they must also be used for an existing room as well. In the same project, the decision was made to reuse an existing room as an electrical room. In this case, the use of an existing storage room had sufficient space for all the electrical equipment (see Figure 2).

Figure 2

When designing electrical rooms with more equipment, MCCs, larger transformers, higher voltages, etc. or searching for existing spaces to house equipment, there are several factors to consider:

- Size of new electrical equipment

- Voltage of new electrical equipment

- Total load of new electrical equipment

- Access and egress of new electrical room/space

- Protection of electrical equipment

- Proximity to combustible gases and/or materials

Other factors that need to be taken into consideration when sizing a room, or space, include proximity to combustible gas relief devices or vents, and its proximity to flammable materials. The customer must be made aware of the hazards of ignoring these rules, since they can lead to equipment damage, and/or harm to personnel.

If an existing space in the building is allocated for electrical equipment, instead of a dedicated electrical room, there must be provisions made to protect the equipment, as well as anyone that may need to work on said equipment. This can be done by marking the floor with tape at a proper distance from the equipment, barriers, or signage (see Figure 3). The customer must be made aware of the rule that restricts the area being used as storage or other uses, as this often becomes an issue regardless of signage (see Figure 4). When this rule is ignored, maintenance on the equipment becomes difficult, a fire hazard can be created, and the possibility of harm to personnel rises if there is an emergency.

Figure 3

Figure 4

Ontario Electrical Safety Code (OESC) References

The following rules found in the Ontario Electrical Safety Code (OESC) must be used when sizing an electrical room or space:

- 2-200 General

- 2-300 General requirements for maintenance and operation

- 2-308 Working space around electrical equipment

- 2-310 Entrance to, and exit from, working space

- 2-312 Transformer working space

- 2-320 Illumination of equipment

- 2-322 Flammable material near electrical equipment

- 2-324 Ventilation

- 2-328 Electrical equipment near combustible gas equipment

- Table 56 Minimum working space around electrical equipment having exposed live parts

When choosing an area, or electrical room to install new electrical equipment, one shall also take into consideration the “Safe Work Distance” rule (Canada Occupational Health and Safety Regulations 8.5 (6 a,b)), IF there is any existing unguarded, uninsulated, or ungrounded equipment present. This distance varies according to the voltage and can be found in the chart below:

Table 56

| Voltage Range of Equipment to Ground | Distance in Metres (Unqualified Person) | Distance in Metres (Qualified Person) |

|---|---|---|

| Over 425 to 12,000 | 3 | 0.9 |

| Over 12,000 to 22,000 | 3 | 1.2 |

| Over 22,000 to 50,000 | 3 | 1.5 |

| Over 50,000 to 90,000 | 4.5 | 1.8 |

| Over 90,000 to 120,000 | 4.5 | 2.1 |

| Over 120,000 to 150,000 | 6 | 2.7 |

| Over 150,000 to 250,000 | 6 | 3.3 |

| Over 250,000 to 300,000 | 7.5 | 3.9 |

| Over 300,000 to 350,000 | 7.5 | 4.5 |

| Over 350,000 to 400,000 | 9 | 5.4 |

| Over 425 to 12,000 | Column 2 Value 11 | Column 3 Value 11 |

Illustrations

The following illustrations and photographs can be used as a guide, in conjunction with the listed rules:

Examples based on 2-310

Examples of proper spacing and marking:

Examples of improper procedures: