Commissioning a Standardized Treatment System at Organic Waste Processing Plant

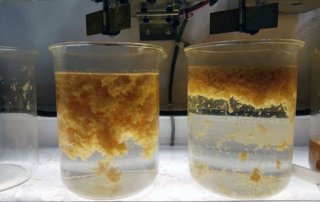

Most restaurants and factories have grease traps and interceptors, sump pits, and sludge waste holding tanks. These traps and tanks are emptied and cleaned out on a regular basis by vacuum trucks that offload at a central processing plant. JNE Environmental supplied equipment and chemicals to create a standardized treatment system at a series of these plants.