Cost-Effective Polymer Make Down and Preparation Unit

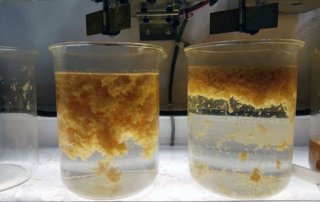

JNE Environmental has developed a very cost effective dry polymer make down and preparation unit. This system is fully automatic and can prepare 1,000 litres of properly mixed and aged polymer every 2.5 hours with an accuracy of +/- 0.0002% by weight.